Capabilities

Knowledge

MGB has developed its micromachining knowledge over approximately 70 years.

In complete confidentiality, we support our customers in performing innovative projects.

Whether it be on fixed or mobile headstock machines, we manufacture parts:

- from Ø ¹/₆₄ “ to Ø 3 ¹⁵/₁₆” (from Ø 0.2 mm to Ø 100 mm)

- up to 15 ³/₄ “ in length (400 mm)

- in metal alloys or plastic

- for lots from 10 to 500,000 pieces

We provide full service: co-development, machining, deburring, heat treatments, partial annealing, and in-house assembly, all while ensuring the management of external contractors.

Innovation

Investments

MGB dedicates 8 to 10% of its turnover each year to investment. This provides our employees with effective tools, stimulating them to anticipate market needs and to innovate.

Co-development

By intervening early, already during product conception, MGB has become a source of innovation for its customers when launching new, inventive products.

The pros of co-development:

- Reduce your development costs by benefiting from MGB’s expertise for mechanical parts

- Consider production requirements during the design phase

- A single contact from industrialization through production

- Guarantee confidentiality

Analyze

Design

- Assembly study

- Choice of the materials and surface treatments

- Detail plan processing

- Assembly simulation

- Prototypes

- Mechanical performance validation

Industrialize

- Pre-series

- Product and process qualification

Optimize

Serial production

Markets

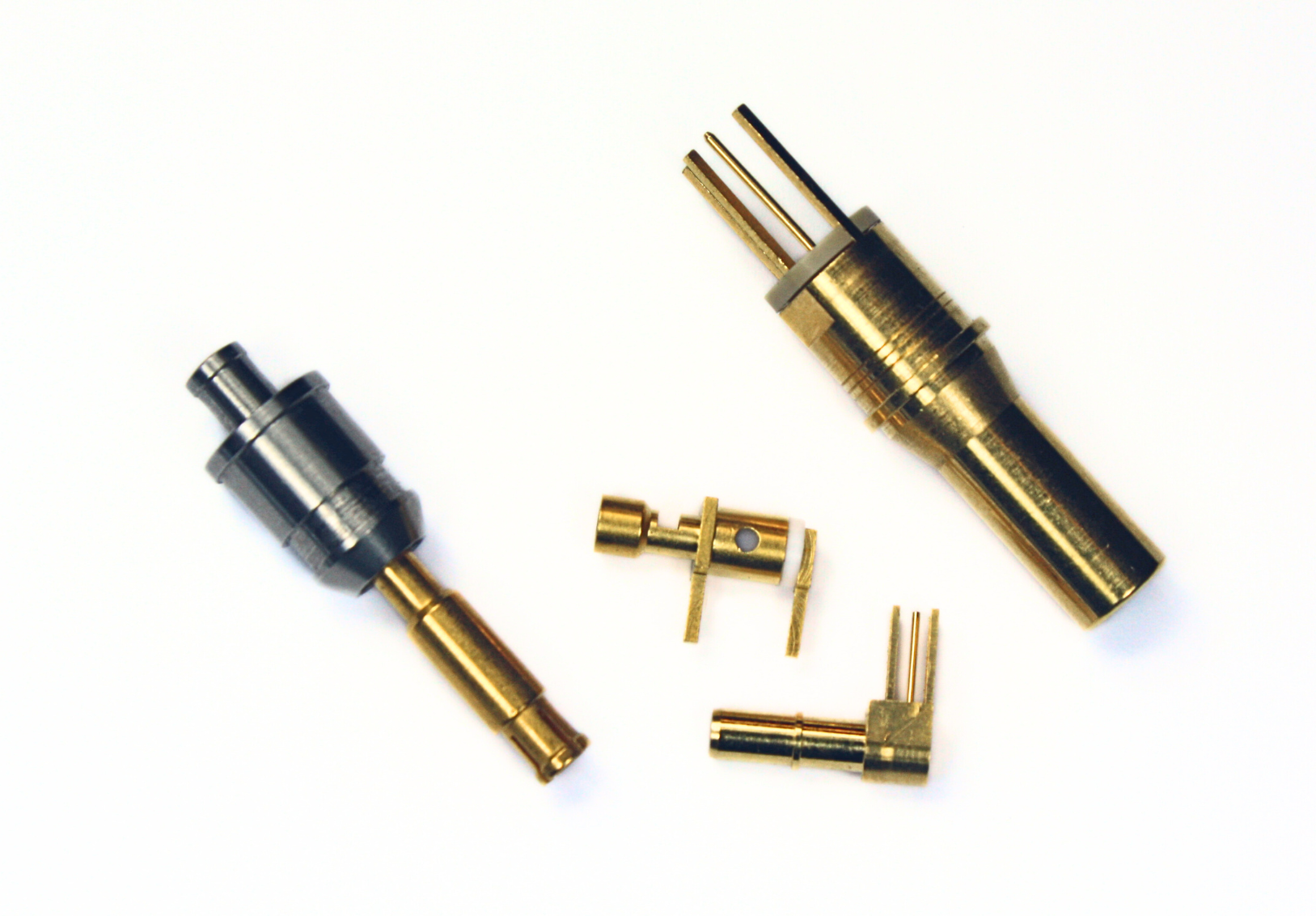

Connectors

Coax connectors: co-development and manufacture of contacts, bodies, and insulators. Assembly. Assembly.

Medical

Space

Coax and fiber-optic connectors.

Aeronautic

Military

Certifications

MGB’s expertise is translated by its proactive management of our customer’s specific needs, consolidating a relationship of confidence

based on the satisfaction and excellence of the products delivered. From order acceptance to shipping, through document management,

our quality process ensures the compliance of our products.

This engagement has been repaid with:

Commitment

- Guide them through development and provide our expertise to optimize their performance

- Be an active partner, offering knowledge dedicated to fulfilling their project and continuously improving their products

- Meet their requirements, quality needs, and service index

- Respect confidentiality

We have committed to our employees to:

- Provide a fulfilling work environment

- Supply tools for high-performance work, dedicating 8 to 10% of our turnover to investments

- Apply the principles of our CSR charter