Equipment

Machining

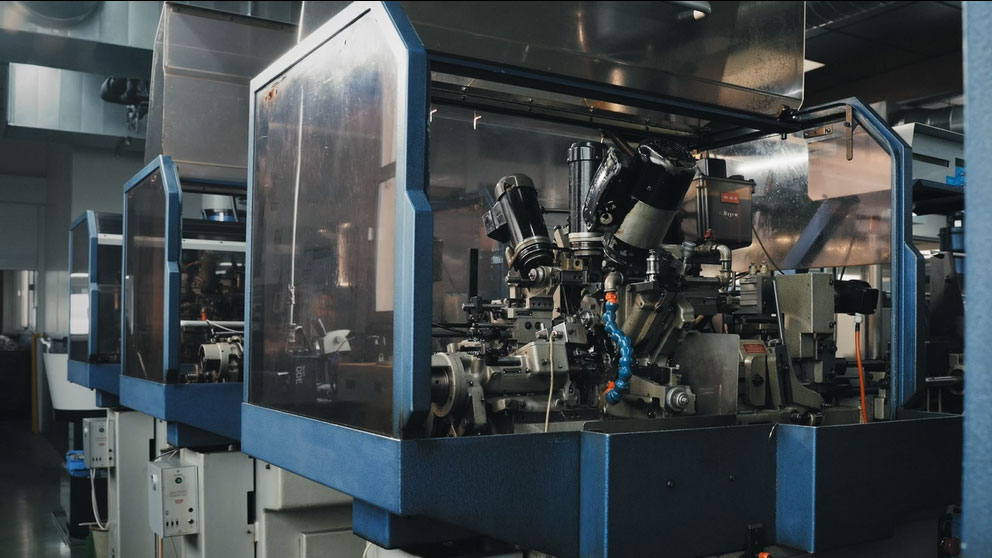

Machining is a demanding field that requires high-performance, reliable production equipment.

At the heart of MGB are the Tornos high-precision machine tools found in the machine fleets at all our locations in France, the United States, and China. The use of the same equipment at the core of the MGB gives us great flexibility in meeting our customers’ needs, wherever they may be, for lots ranging from 10 to 500,000 parts.

In a world full of uncertainty, a uniform machine fleet in Europe, North America, and Asia provides security for our customers in a crisis, one MGB site can pick up for another to satisfy the most urgent requirements

Fleet renewal

A reliable machine fleet also requires regular equipment renewal. Investment is essential to being innovative, competitive, and proactive in the world market.

Sliding headstock

At the core of MGB’s production capacity are the Tornos mobile headstock machine tools. They allow us to manufacture most of our machined parts with diameters of ¹/₆₄ “ (0.2 mm) on the Nanos to 1 ¹⁷/₆₄” (32 mm) diameter on the EvoDeco.

Fixed Headstock

MGB recently added three fixed-headstock machine tools to its machine fleet to increase capacity and address customers’ varying needs. This diversification allows machining parts up to 7 7/8” (200 mm) diameter from bars or billets.

Large lots

Cam and Hydromat machines

Being on the cutting edge of innovation does not mean turning your back on proven technology. Robust, repeatable, and reliable, our twenty-four MS7 cam machines in France and ten Hydromat transfer machines in China still meet the needs of our customers for large lots today.

MGB US

16 Machines

- 10 Tornos Deco 7 – 10

- 3 Tornos Deco 13

- 2 Tornos Deco 20

- 1 Tornos Delta 20

MGB France

75 Machines

-

28 Tornos EvoDeco 10

-

12 Tornos EvoDeco 16

-

6 Tornos EvoDeco 32

-

22 Tornos MS 7

-

1 Tornos Nano 4

-

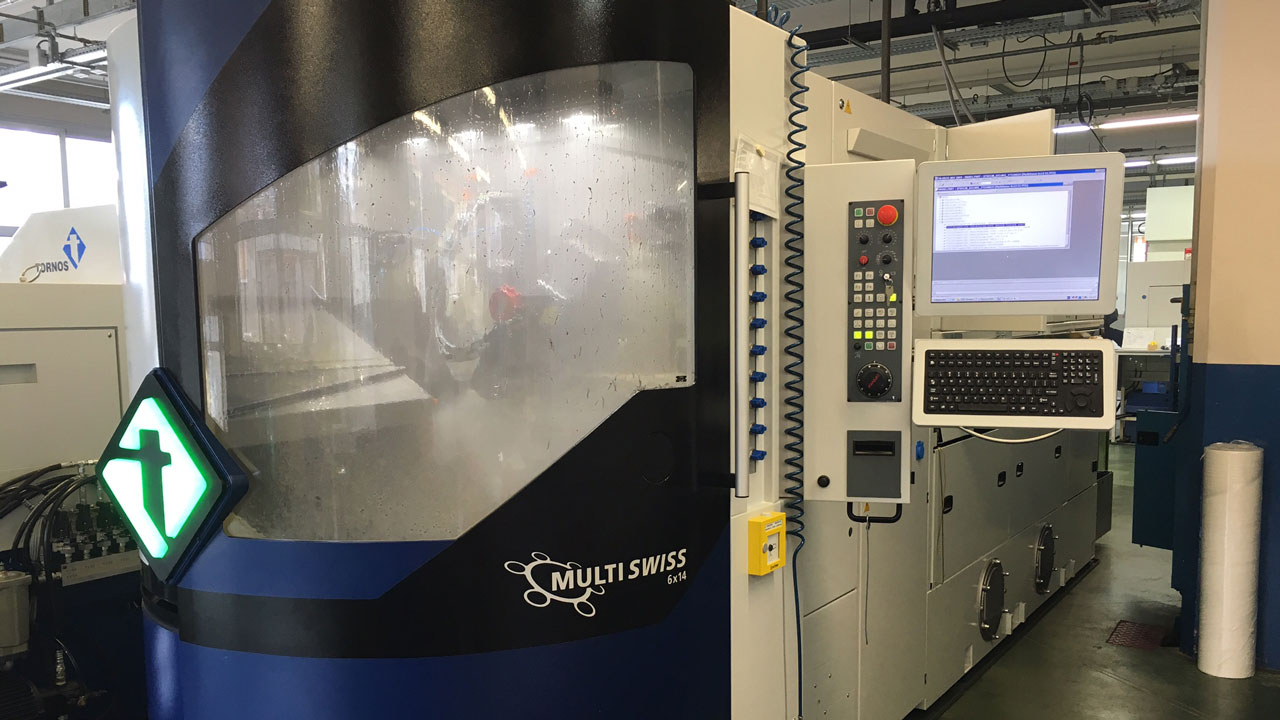

1 Tornos MultiSwiss 6×14

-

1 Tornos Gamma 20

-

1 Tornos GT 26

-

1 DMG MORI NLX 150

-

1 Biglia B 550 YS

-

1 DMG MORI NTX 500

MGB China

37 Machines

- 19 Tornos Deco 7 – 10

- 4 Tornos Deco 13

- 2 Tornos Nano 4 – 7

- 1 Tornos Delta 20/5

- 1 Tornos Sigma 32

- 10 Hydromat HW25/12

Finishes

Beyond machining… is full service.

To respond to the demands of our customers, MGB provides an organization with fully integrated complementary operations. Reactivity and expertise in several areas are provided to reduce supply times.

Deburring

Internal control of deburring operations: tribofinishing, sandblasting, polishing.

Heat treatments

Internal control of finish processes, such as heat treatments under a protective atmosphere and partial annealing.

Surface treatments

Control of surface treatments in France and abroad. Major industry players have approved our surface treatment partners.

Branding

Internal control of the marking and identification process: laser marking, stamping.

Assembly

Internal control of assembly operations: semi-automatic, easily configured based on the products to assemble, manual

International Logistics

International logistics are based on relationships with proven transportation partners, our production subsidiaries, and our foreign stocking platforms (USA, China, and Switzerland).

Packaging

Internal control of packaging operations: manual or semi-automatic packaging machine, in small bags or on trays with barcodes and installation instructions.

Identification

Internal control of the barcode identification using MGB OF when entering stock at customers’ plants.

Industries of the Future

Innovation has always been a part of MGB’s DNA. We strive for excellence, pushing ourselves beyond the boundaries of our areas of expertise. Each day, MGB employees endeavor to anticipate future evolution and to work to shape the industry of tomorrow proactively.

Labels

Objectives:

- Improve the customer service index (OTD)

- Ensure the traceability of lots

- Digitalize orders and facilitate access to them

Solution:

Deploy 500 labels with ultra-low consumption displays.

Function:

- Dynamic labeling of a lot’s status (Early/Late) and deducting the days remaining to operate.

- GPS tracking of the parts in the shop.

- Access to instructions related to the reference by simply scanning a QR code

Capitalization tablets

Objectives:

- Improve the customer service index (OTD)

- Capitalize the knowledge accumulated by our employees in 70 years of business

- Facilitate training

- Develop versatility

Solution:

Deployment of ten numerical tablets in the workshop and development of a dedicated app, also accessible by computer

Function:

- Record good working practices, tricks, and tips

- Illustration using photographs or videos

- Easy to consult thanks to research by topic and keyword

FabLab

Does what you need not exist? Let’s make it!

Whether for additional elements optimizing production, anti-FOD lids, or even supports, MGB encourages its employees to demonstrate their ingenuity and develop custom solutions as needed. To do this, we have a 3D printer milling machine in service in addition to production or assembly tools.

Creativity never stops at the company’s perimeter. FabLab is available for personal growth.

Cybersecurity

Since cybersecurity is a real issue in guaranteeing the confidentiality of our customers’ orders, MGB has committed to securing its computer system.

With recommendations from experts and in the framework of Boost Aerospace AirCyber, we have increased our level of computer security maturity. Today, we can ensure our partners’ confidentiality, integrity, and availability of their numerical information.

Control-metrology

Our parts are controlled by demanding, ISO 9001-certified processes from planning to shipment.

Our parts are controlled by demanding, ISO 9001-certified processes from planning to shipment. Our internal control-metrology service verifies the compliance for the most complex products.

To do this, in addition to conventional dimensional controls, we are equipped with the following:

- Three-dimensional control machine

- Two-dimensional control machines

- Durometers

- Profilometers

- Torque wrenches

- Roughness meters

Certifications

MGB’s expertise is translated by its proactive management of our customer’s specific needs, consolidating a relationship of confidence

based on the satisfaction and excellence of the products delivered. From order acceptance to shipping, through document management,

our quality process ensures the compliance of our products.

This engagement has been repaid with:

Commitment

We have engaged in reliable production with the latest-generation machines to accompany and follow our customers’ performance. Whether during product development or production, our routine investments allow us to anticipate market needs, ensuring traceability, service index, and product compliance to customers’ expectations or markets’ demands.

We are committed to providing our employees with tools that promote professional development and allow them to work optimally. Providing everyone with the resources to excel in their jobs, contributes to work efficiency, motivation, and satisfaction.

Would you like more information?

Please fill in the contact form so our sales team can contact you.